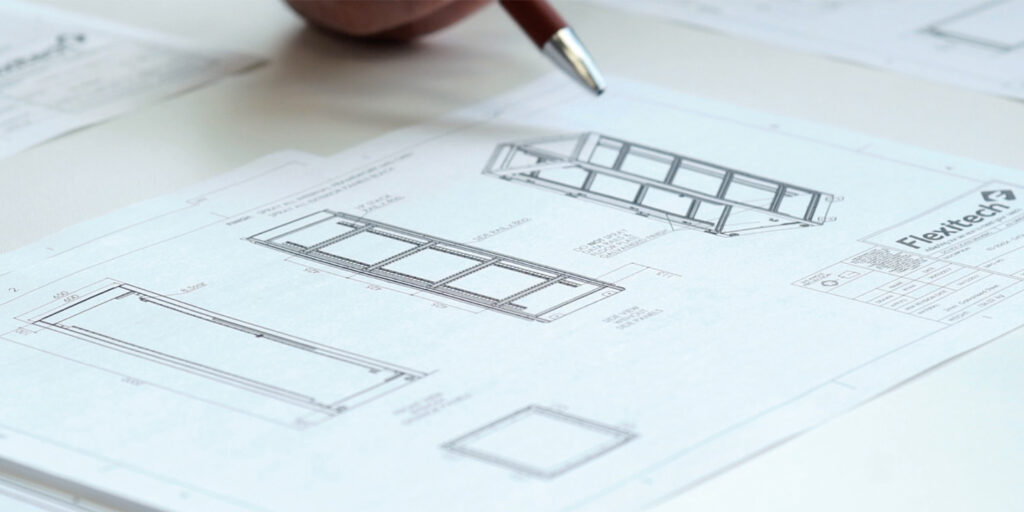

State-of-the-Art Technology

Flexitech has invested significantly in state-of-the-art technology including high-tech robotic automation equipment.

This enables us to run our fabrication services at maximum efficiency and pass the resulting cost savings to our clients, which results in competitively priced manufacturing processes operating to the highest levels of quality and accuracy.

Since 2000, Flexitech Ltd has become an invaluable supply-chain partner to the Anord Group, providing us with quality sheet metal and forming copper products.

Paul Roddy

“Their attention to detail, on-time delivery, value and willingness to adapt their business to meet the demands of ours means that they have consistently been amongst our top 3 vendors since we first started trading with them.”

Group Head of Procurement, Anord

What Makes Us Different?

- We have the latest high tech equipment a CAD system with full 3D modelling capabilities.

- Our highly skilled team of professionals can cope with one-off requests and devise elegant solutions for the most intricate and challenging manufacturing requests.

- The Flexitech team work on a multi shift basis which allows us to be flexible when working to tight deadlines and dealing with substantial orders.

- Flexitech utilises a wide range of manufacturing materials including mild steel, galvanised steel, PVC, stainless steel and aluminium.

Quality components, efficient production

Copper

Flexitech processes copper busbars. Busbars can be bare or tinned, punched and cut to length and breaker copper kits made to customer drawing spec.

Current range of copper:

• 5mm

• 6mm

• 8mm

• 10mm

Flexitech adopts the highest standard of care and attention to detail in providing a comprehensive range of manufactured Copper services such as copper forming and part/kit production. Flexitech has an experienced and dedicated team to supply a range of bespoke copper products. Also have capabilities to offer insulated copper to customers’ specification.

Steel

Flexitech manufacture a range of various types and thickness materials such as:

• Zintec and Galvanised in various thicknesses from 0.5mm to 8mm

• Aluminium and stainless various grades & thickness

• Polycarbonate

• GP03

• Fibon

• Foamex and etc.

Flexitech sheet metal services include:

• Design & CAD Drawings

• Cutting, punching & folding

• Welding

• Powder Coating

• Assembly

Stainless Steel

We supply stainless steel product in various grades and thickness depending on the need of our partners.

Powder Coating

Flexitech has its own in house Powder Coating facility with the latest spray equipment. Highly skilled operators are dedicated to quality finishing and this has been reported back to us by our customers many times. We have capabilities to offer powder coating to suit most requirements in batch runs as well as in one offs suitable for indoor or outdoor use. The in-house Powder Coating facility allows Flexitech to offer customers competitive lead times and complete turnkey fabrication solutions. All our Powder Coated parts are tested for thickness of the paint to ensure quality standards, prior to dispatch.

Welding

Our well trained and experienced welding team can weld in MIG, TIG and ARC. We use the most modern welders which allow us to weld mild steel, stainless steel and aluminium.